The World Needs An Unplugged Electric Car.

The Electric Car: My Thoughts, My Notes, My Dream, Our Hope.

(When You Build It: They Will Buy It.)

What is needed is for someone to step way out of the box and create a Kinetic Energy Recovery System that literally harvests energy from the motion and vibration of the vehicle and turns into electricity that can used/stored to recharge the battery system of the automobile. That motion can be Linear, rotational and vibrational motions, all of which can be used to generate electricity. Human ingenuity knows few limits. Currently KER Systems have been limited to regenerative braking energy, but an automobile no matter how luxurious the drive is loaded with kinetic energy with things moving in every which way. That energy can be harvested and utilized in the creation of a true zero emissions, unplugged revolutionary vehicle. At least, if not a replacement for battery driven electric vehicles, advanced KERs can provide my long sought on-board auto recharging system for those batteries. The thesis of this post is simply: Every automobile is a virtual farm of Kinetic energy and that it ought to be harvested and harnessed to complete the dream of a TRUE ELECTRIC CAR! Certainly we are intelligent enough to move from harnessing Kinetic energy from vehicle braking to collecting it all, or enough, to create a new automotive reality. Throw away the recharging umbilical cord; forget recharging stations and overnight charging in your garage or driveway, forget the internal combustion engine and consign it to the bone yard of history and museums, forget the oil companies..They have had their day of profit plundering and criminal capitalism. And Yes, I favor Tesla Autos to get there first. Contact them with this message, this post. |

There a number of Hybrid/Gas/Electric Cars and very few true Zero emissions electric cars, and most of them are as yet severely limited in their long range driving abilities. OK, so they have to be plugged in to a source of electricity to recharge their batteries/battery pack. While it is true that electricity is less expensive than gasoline; we still don’t have a true green vehicle because somewhere something is being consumed to produce that electricity.

Chevy’s E-Volt has not generated the interest or excitement that had been hoped for. The Nissan Leaf has severe limitations, but Nissan engineers are forging ahead with their R&D.

But in the media shadows an upstart, startup company, Tesla Motors could well be the winner in the race the true green, true electric car that will revolutionize the automotive industry.

NOTE: Tesla Motors [NSDQ: TSLA] has a market capitalization of $2.5 billion, after its successful initial public offering last June.

Tesla has built barely 1,700 cars, and will produce no cars at all during a substantial part of next year as it works toward volume production of its all-electric 2012 Tesla Model S luxury sports sedan

The Tesla Roadster, the company's first vehicle, is the first production automobile to use lithium-ion battery cells and the first production EV with a range greater than 200 miles (320 km) per charge.[7] The base model accelerates 0–60 mph (97 km/h) in 3.9 seconds and, according to Tesla Motor's environmental analysis, is twice as energy efficient as the Toyota Prius.[8] As of January 2011, Tesla had delivered more than 1,500 Roadsters in at least 30 countries.[9] Tesla has said that it will produce a total serial production run of 2,400 Roadsters.[10] Tesla began producing right-hand-drive Roadsters in early 2010 for the UK and Ireland markets, then expanded sales to right-hand-drive markets of Australia, Japan, Hong Kong and Singapore.[11]

Tesla is currently developing the Model S, an all-electric family sedan. Tesla unveiled the car March 26, 2009 with an anticipated base price of US$57,400 (or US$49,900[12] after a US federal tax credit). The Model S will have three battery pack options for a range of up to 300 miles (480 km) per charge.[13] As of January 2011, Tesla has taken about 3,500 reservations for the Model S and expects to begin delivering cars to customers in 2012.[9] Tesla currently employs almost 900 full time employees[1] and is aggressively recruiting employees for positions in the headquarters in Palo Alto, California; at its European headquarters in Maidenhead, UK; and at an increasing number of sales facilities throughout North America and Europe.[14] Tesla plans to build the Model S in 2012[15] in Fremont, California in an assembly plant formerly operated by NUMMI, a now defunct joint venture of Toyota and General Motors.[16]

Tesla purchased a stake in the site in May 2010 for US$42 million,[15][17] and opened the facility in October 2010 as the Tesla Factory.

Tesla Motors was incorporated in Delaware on July 1, 2003 by Martin Eberhard and Marc Tarpenning to pursue serial production of AC Propulsion's tzero prototype electric sports car.[29] With a limited amount of personal funding, they rented Tesla's first office in Menlo Park, California and began developing a skeletal business plan to commercialize the electric sports car.

They added Ian Wright to the team and in January 2004 started looking for funding to develop a production electric sports car. They arranged with AC Propulsion to borrow their TZero prototype to demonstrate to potential investors the performance possible with an electric car.

Independently, entrepreneur Elon Musk had been developing a business strategy to commercialize electric vehicles on a far broader scale, starting with a premium sports car aimed at "early adopters" and then moving as rapidly as possible into more mainstream vehicles, including sedans and compacts.[30] After his first meeting with Eberhard and Tarpenning, Musk took an active role within the company and oversaw Roadster product design;[31] in fact, Eberhard acknowledged that Musk was the person who insisted from the beginning on a carbon fiber body, and he led design of components ranging from the power electronics module to the headlamps and other styling cues.[32]

In addition to his daily operational roles, Musk also became the lead investor, funding the vast majority of the Series A capital investment round of US$7.5 million with personal funds. Musk also became Tesla's Chairman of the Board, recruited JB Straubel to become chief technology officer and greatly expanded Tesla's long-term strategic sales goals to mainstream vehicles to be developed after a sports car.[33] Musk received the Global Green 2006 product design award for his design of the Tesla Roadster, presented by Mikhail Gorbachev,[34] and he received the 2007 Index Design award for his design of the Tesla Roadster.[35]

Musk's Series A round included Compass Technology Partners and SDL Ventures, as well as many private investors. Musk later led Tesla Motors' Series B, US$13 million, investment round which added Valor Equity Partners to the funding team. Musk co-led the third, US$40 million round in May 2006 along with Technology Partners. Tesla's third round included investment from prominent entrepreneurs including Google co-founders Sergey Brin & Larry Page, former eBay President Jeff Skoll, Hyatt heir Nick Pritzker and added the VC firms Draper Fisher Jurvetson, Capricorn Management and The Bay Area Equity Fund managed by JPMorgan Chase.[36]

The fourth round in May 2007 added another US$45 million and brought the total investments to over US$105 million through private financing.

In December 2007, Ze'ev Drori became the CEO and President of Tesla Motors. In January 2008, Tesla Motors fired several key personnel who had been involved from the inception after a performance review by the new CEO.[37] According to Musk, Tesla was forced to reduce the company workforce by about 10 percent to lower its burn rate, which was out of control in 2007.[38]

The fifth round in February 2008 added another US$40 million. Musk had contributed US$70 million of his own money to the company by this time.[39] In October 2008, Musk succeeded Ze'ev Drori as CEO. Drori became Vice Chairman. He left the company in December. By January 2009, Tesla had raised US$187 million and delivered 147 cars.[38][40]

On May 19, 2009, Germany's Daimler AG, maker of Mercedes, acquired an equity stake of less than 10 percent of Tesla for a reported US$50 million.[41] In July 2009, Daimler announced that Abu Dhabi's Aabar Investments bought 40 percent of Daimler's interest in Tesla.[42]

In June 2009 Tesla was approved to receive US$465 million in interest-bearing loans from the United States Department of Energy. The funding, part of an US$8 billion program for advanced vehicle technologies (Advanced Technology Vehicles Manufacturing Loan Program), supports engineering and production of the Model S sedan, as well as the development of powertrain technology that Tesla plans to sell to other automakers.[43]

The low-interest loans are not related to the "bailout" funds that GM and Chrysler have received, nor are they related to the 2009 economic stimulus package. The Department of Energy loan program was created in 2007 during the George Bush administration in order to get more fuel-efficient vehicle options to U.S. consumers and to decrease the country's dependence on foreign oil.[44]

The company announced in early August 2009 that it had achieved overall corporate profitability for the month of July 2009.[45] The company said it earned approximately US$1 million on revenue of US$20 million. Profitability arose primarily from improved gross margin on the 2010 Roadster, the second iteration of Tesla’s award-winning sports car. Tesla, which like all automakers records revenue when products are delivered, shipped a record 109 vehicles in July and reported a surge in new Roadster purchases.

In September 2009, Tesla announced an US$82.5 million round to accelerate Tesla's retail expansion in advance of the Model S.[46] Daimler participated in the round to maintain equity ownership from its initial investment. A new investor was Fjord Capital Partners, under the leadership of founders Michael Obermayer (a former senior partner and director of McKinsey & Company, Inc), Arild Nerdrum and Xavier de La Rochefoucauld. Fjord is a specialized European private equity manager investing into the clean energy sector globally. Fjord invests growth capital in renewable and low-carbon companies and projects.

Tesla Motors signed a production contract on 11 July 2005 with Group Lotus to produce "gliders" for Tesla.[47] Tesla Motors originally signed a production contract with Group Lotus good through March 2011, but the two automakers revealed they have extended the deal to keep the electric Roadster in production through December 2011 with a minimum number of 2,400 units,[48] when production is unlikely to continue mostly because of tooling changes orchestrated by one of its suppliers.[49]

On 29 January 2010, Tesla Motors filed Form S-1 with the U.S. Securities and Exchange Commission,[50] as a preliminary prospectus indicating its intention to file an initial public offering underwritten by Goldman Sachs, Morgan Stanley, J. P. Morgan and Deutsche Bank Securities. In a standard S-1 update filed March 26, Tesla added fourth-quarter 2009 data to the initial filing. According to the update, Tesla sold 937 Tesla Roadsters to customers in 18 countries and generated US$126.8 million in revenue as of Dec. 31, 2009.[51] On May 21, 2010, Tesla announced a "strategic partnership" with Toyota, which agreed to purchase US$50 million in Tesla common stock issued in a private placement[52][53] to close immediately after Tesla's planned IPO.[54]

Executives at both companies said that they would cooperate on "the development of electric vehicles, parts, and production system and engineering support."[53] Less than two months later, Toyota and Tesla confirmed that their first platform collaboration would be to build an electric version of the RAV4 EV.[55]

In June 2010, it was reported that Tesla sold a total of US$12.2 million zero emission vehicle credits to other automakers, including Honda, up to March 31, 2010.[56] On June 29, 2010 Tesla Motors launched its initial public offering on NASDAQ under the symbol TSLA.

The IPO raisedUS$226 million for the company.[57] It was the first American car maker to go public since the Ford Motor Company had its IPO in 1956.[58]

Tesla builds and sells its own cars, but unlike many traditional manufacturers it also operates as an original equipment manufacturer, or OEM, manufacturing electric vehicle powertrain components that other automakers may purchase and retail under their own brand names. Tesla has confirmed partnerships with two other automakers, Daimler and Toyota. Tesla also works closely with Panasonic as a strategic partner in battery cell research and development. The company is supplying battery packs for Freightliner Trucks's Custom Chassis Electric Van.[85]

Starting in late 2007, Daimler and Tesla Motors began working closely to integrate Tesla’s lithium-ion battery packs and charging electronics into the first 1,000 units of Daimler’s electric smart car. The two companies are expected to collaborate further, including working together on the Tesla Model S sedan. The collaboration is not expected to result in co-branded cars or the sale of Mercedes vehicles in Tesla showrooms, or vice-versa.

On May 19, 2009, Germany's Daimler AG, maker of Mercedes, acquired an equity stake of less than 10 percent in Tesla for a reported US$50 million.[41][101] As part of the collaboration, Prof. Herbert Kohler, Vice President E-Drive and Future Mobility at Daimler AG, took a seat on Tesla’s board of directors.[102]

On July 13, 2009, Daimler AG sold 40 percent of their May acquisition to Aabar Investments PJSC. Aabar is an investment company controlled by the International Petroleum Investment Company (IPIC), which is wholly owned by the Government of the Emirate of Abu Dhabi.[103][104] (In March 2009, Aabar purchased a 9 percent stake in Daimler for 1,95 billion EUR.)

On May 20, 2010, Tesla and Toyota announced a partnership to work on electric vehicle development, which included Toyota's US$50 million future conditional investment[53] in Tesla and Tesla's US$42 million purchase of a portion of the former NUMMI factory.[15][16] Musk said the Model S sedan will be built at the plant, which is about 20 miles (32 km) east of the company's headquarters in Palo Alto, California.[105] Tesla and Toyota also said that they intend to cooperate on the development of electric vehicles, parts, and production system and engineering support. It was announced that an electric version of the Toyota RAV4 would be mass produced in 2012.

Panasonic Energy Company President Naoto Noguchi presented Tesla CTO JB Straubel with the first production Lithium-ion cells manufactured at Panasonic's facility in Suminoe, Japan.

On January 7, 2010, Tesla and battery cell maker Panasonic announced that they would together develop nickel-based lithium-ion battery cells for electric vehicles. Naoto Noguchi, President of Panasonic’s Energy Company, said the Japanese firm’s cells will be used for Tesla’s “current and next-generation EV battery pack.”[106] The partnership was part of Panasonic's US$1 billion investment over three years in facilities for lithium-ion cell research, development and production. Tesla disclosed that the new cell resulting from its collaboration with Panasonic will allow Tesla to continue using cells from multiple suppliers.[107]

In April 2010, Panasonic Energy Company President Naoto Noguchi presented Tesla Chief Technology Officer JB Straubel with the first production Lithium-ion cells manufactured at the new facility in Suminoe, Japan. The Suminoe factory will start producing 3.1Ah battery cells, the highest energy density cells available in the market. The facility will produce more than 300 million cells per year.[108]

On 5 November 2010, Panasonic invested US$30 million for multi-year collaboration on the development of next generation battery cells designed specifically for electric vehicles.[109]

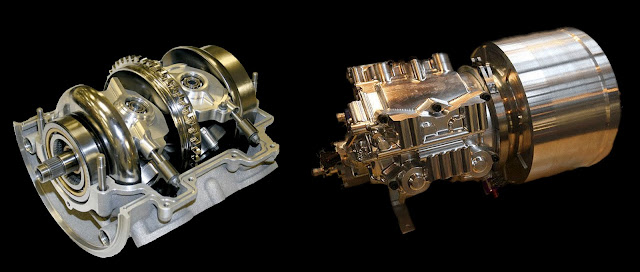

Like virtually all production cars, the Tesla Roadster uses parts from around the world. Tesla's power train, which is proprietary, is designed and built in California.

Tesla Motors maintains relationships with dozens of suppliers for other parts of the car, including Tesla's carbon fiber body panels which are made in France by Sotira. The panels are sent to England, where Tesla contracts with Lotus to build a unique chassis in Hethel, U.K.

The cars are then sent to Menlo Park, California, where workers install all of the proprietary intellectual property of the car.

The battery pack is assembled in Palo Alto, California, using battery cells from Japan. The single-speed gearbox is built by Michigan, USA-based supplier BorgWarner.

When the company began in 2003, Tesla licensed AC Propulsion's Reductive Charging patent, which integrates the charging electronics into the inverter in a way that reduces mass and complexity.

Shortly after the company's founding, Tesla Motors developed a power train well beyond what the company initially licensed from AC Propulsion.

The company no longer employs any of AC Propulsion's original intellectual property.[28]

Any electric car that uses batteries needs a charging system to recharge the batteries. The charging system has two goals:

· To pump electricity into the batteries as quickly as the batteries will allow

· To monitor the batteries and avoid damaging them during the charging process

The most sophisticated charging systems monitor battery voltage, current flow and battery temperature to minimize charging time. The charger sends as much current as it can without raising battery temperature too much. Less sophisticated chargers might monitor voltage or amperage only and make certain assumptions about average battery characteristics. A charger like this might apply maximum current to the batteries up through 80 percent of their capacity, and then cut the current back to some preset level for the final 20 percent to avoid overheating the batteries.

Nissan Leaf

Your Nissan LEAF™ is built to go 100 miles on a single charge(1)

How far you'll go will depend on a number of variables

a fully charged new battery has a range of 138 – 62 miles. range is most affected by the following factors:

Climate control – the more extreme the temperature is outside, the more energy used to heat or cool the cabin. Speed – higher speeds require much more energy to overcome air resistance. Driving style – smooth acceleration and deceleration will extend range while aggressive acceleration and deceleration will decrease range.

Cargo and topography – heavy cargo and driving up steep long inclines will

reduce range.

The Nissan LEAF has been tested under the EPA Urban Dynamometer Driving Schedule, a laboratory test commonly called the LA4 test cycle, which represents city driving conditions. Top speed is 56.7 mph and average speed is 19.59 mph. Ambient temperature can vary from 68 - 86 degrees. Climate control is off. The Nissan LEAF easily achieved 100 miles.

Ideal driving conditions: 138 miles

Speed: Constant 38 mph

Temperature: 68 degrees

Climate control: Off

Driving on a flat road at a constant 38 mph means less air resistance, and therefore less energy use. And at 68 degrees, there's no need for climate control, extending the range even further. The result: a range boost up to 138 miles.

Suburban driving on a nice day: 105 miles

Speed: Average 24 mph

Temperature: 72 degrees

Climate control: Off

The average speed in this scenario is 24 mph; common when commuting and running errands. The ambient temperature is 72 degrees and the climate control is off. Not using the air conditioner and driving at slower speeds mean less energy use and a little extra range.

Highway driving in the summer: 70 miles

Speed: Average 55 mph

Temperature: 95 degrees

Climate control: On

Averaging 55 mph on the highway, in 95 degree weather, with the air conditioning on high may produce range figures like this. Higher speeds require more energy to overcome air resistance. Running the air conditioner means energy that could be used to increase range instead goes to cooling the car.

Cross-town commute on a hot day: 68 miles

Speed: Average 49 mph

Temperature: 110 degrees

Climate control: On

Driving from a rural area into the city at an average 49 mph with the a/c on high may produce this range. Under these conditions, climate control combined with higher-speed driving produces increased energy consumption, hence the effect on range.

Winter, urban stop-and-go, traffic jam: 62 miles

Speed: Average 15 mph

Temperature: 14 degrees

Climate control: On

Though the average speed is only 15 mph with stop-and-go traffic, the 14-degree temperature means the heater is doing a lot of work so you spend considerable time and energy heating your car rather than moving forward. Despite these conditions, it would still take more than 4 hours to run out of charge!

Disclaimers:

(1) 100 miles based upon EPA LA4 city cycle conducted in laboratory tests.

(2) Seehttp://www.fueleconomy.gov/feg/fe_test_schedules.shtml. Based upon EPA five-cycle tests using varying driving conditions and climate controls, the EPA has rated the Nissan LEAF a driving range of 73 miles. Battery capacity decreases with time and use. Actual range will vary depending upon driving/charging habits, speed, conditions, weather, temperature, and battery age.

Tesla Motors http://www.teslamotors.com/models

Control in an instant. Feedback and information within arm's reach. Comfort surrounds the driver.

Carry anything needed for a day, a trip, an unexpected shopping spree. The Model S offers luxurious space, seating for five adults and two children, and a second cargo area under the hood.

- Seating for 7

- More cargo space than typical sedans

- Premium interior styling

- More cargo space than typical sedans

- Premium interior styling

Choose from one of three battery pack options to suit typical driving needs: 160, 230, or 300 miles per charge. Concerned with Range Anxiety? Like the Roadster, the Model S is engineered to plug into nearly any outlet, anywhere in the world. With the ability to recharge in 45 minutes, the car begs to be driven everywhere you want to go.

- 160, 230, or 300 mile range pack

- 45 minute QuickCharge

- 45 minute QuickCharge

Model S performance is second to none. The Model S power train offers instant torque at the driver's request. Though designed for comfort, safety, and utility, the coveted Model S does not sacrifice performance. Command control and the Model S delivers the power, acceleration and precise handling of a sports car with quiet simplicity.

- 0-60 in 5.6 seconds

- 120 mph top speed

- 120 mph top speed

The Model S power train features a liquid-cooled, floor-mounted battery pack and single-speed gearbox. The body design is of stamped aluminum and provides top-notch aerodynamics, style, and safety. The 17-inch touch screen with in-car 3G connectivity means quick access to streaming radio, gps navigation, restaurant recommendations, and movie show times

- Leading electric powertrain

- 17-inch touchscreen with 3G connectivity

- Amazing aerodynamics

- 17-inch touchscreen with 3G connectivity

- Amazing aerodynamics

Tesla Motors [NSDQ: TSLA] has a market capitalization of $2.5 billion, after its successful initial public offering last June.

Tesla has built barely 1,700 cars, and will produce no cars at all during a substantial part of next year as it works toward volume production of its all-electric 2012 Tesla Model S luxury sports sedan

And If You Are Like me; This is the question you want answered.

I have a question about the power supply for electric cars. I was reading recently that the plug-in hybrid could have exceptional gas mileage, up to 600 if memory serves, but would have to be plugged in overnight to recharge the battery. I don't understand why an electric car needs to be plugged in to recharge. We have had alternators and voltage regulators in vehicles for years. Why can't someone develop one capable of recharging the battery pack in an electric car so that it doesn't have to be plugged in?

In regular cars, and even in normal hybrids--to a lesser, but similar, degree--the internal combustion engine drives the alternator/generator to keep the battery charged. This works well for two reasons: the engine is already running to keep the car moving, so it’s also available to power the alternator, plus these relatively small starter batteries don’t require much power to keep them charged, so the alternator load is light.

In regular cars, and even in normal hybrids--to a lesser, but similar, degree--the internal combustion engine drives the alternator/generator to keep the battery charged. This works well for two reasons: the engine is already running to keep the car moving, so it’s also available to power the alternator, plus these relatively small starter batteries don’t require much power to keep them charged, so the alternator load is light.

However, in pure electric cars, the battery is the only power supply to the electric traction motor--there is no engine to drive an alternator, and using the electric traction motor to drive an alternator, or act as a generator, would be counterproductive. Since an electric car’s batteries are its only source of power, they are large and require copious amounts of electricity to recharge and must be plugged in.

There is no engine to do that work (though they do employ the assistance of regenerative braking, it is only thus, assistance, and it cannot keep up with demand) and asking the electric motor to charge the battery as well as drive the car would consume most or all of its power.

See the conundrum? In fact, if that actually could be done efficiently, the elusive perpetual energy machine would be a reality. (i.e. the car could produce its own operating energy, and that would be in direct violation of the Law of Conservation of Energy in physics). To paraphrase this law, it states simply that energy can neither be created nor destroyed--it can only change form.

One of those forms is friction. Overcoming the friction of wheels rolling on the road, bearings slipping over journals, and wind resistance (to name just a few) already “changes the form” of some of the car’s energy. It simply cannot magically produce that “lost” power.

Plug-in hybrids are a different animal. In these cars, there is a good size battery pack, traction motor, and a small onboard engine that runs a generator/alternator. Under most folk’s average driving situations, daily commutes would only use up the energy stored in the battery, and then they would be plugged-in again at night for a full recharge for the next day’s tasks. However, under extended use (say, a long distance family vacation), the onboard gasoline powered generator would produce power to directly power the electric traction motors as well as charge the battery. This would allow the car to travel as long as the fuel supply (gasoline) lasted. That’s nice insurance, but it does defeat the purpose of electric drive trains--powering a vehicle without a fuel-burning engine.

This was created by Chip Burcham - he was 20 when he came up with this idea. Here's how it works: Two inner moving bar magnets repel each other. Next, two outer stationary bar magnets repel the two inner moving bar magnets back to each other.

This process works infinitely. While the inner moving bar magnets are moving they each turn a gear. Each of those gears turns an axle and each of those axles turns a horseshoe magnet inside of a coil of wire generating electricity. Thus electricity can be produced forever using this machine.

M2E’s technology, born in the U.S. Department of Energy’s Idaho National Lab, works according to the principle of electromagnetic induction (aka The Faraday Principle). The design consists of a magnetic architecture and coils that create a generator that harvests motion and converts it into an electrical charge. So, even when a device using the generator is in use, it is continuously self-charging. Or so the theory goes. I’m not a physicist.

M2E’s technology, born in the U.S. Department of Energy’s Idaho National Lab, works according to the principle of electromagnetic induction (aka The Faraday Principle). The design consists of a magnetic architecture and coils that create a generator that harvests motion and converts it into an electrical charge. So, even when a device using the generator is in use, it is continuously self-charging. Or so the theory goes. I’m not a physicist.

What is needed is for someone to step way out of the box and create a Kinetic Energy Recovery System that literally harvests energy from the motion and vibration of the vehicle and turns into electricity that can used/stored to recharge the battery system of the automobile. That motion can be Linear, rotational and vibrational motions, all of which can be used to generate electricity.

Burtonsville, MD – November 10, 2009 – New Energy Technologies, Inc. (OTCBB: NENE), a next-generation alternative and renewable energy developer, today announced that engineers developing the Company’s commercial-scale MotionPower™-Heavy device for generating electricity from the movement of heavy trucks, buses, and long haul rigs have made significant breakthroughs in refinement of the technology, including a two-fold increase in its capacity to capture kinetic energy from moving vehicles – the most important factor in maximizing the amount of electricity generated by the system.

Kinetic energy is present in a moving vehicle, much like the energy present in a bicycle, which may sometimes continue to ‘roll’ even though it’s no longer being peddled by the rider. Heavy-duty trucks have up to 25 times more kinetic energy than a typical car traveling at the same speed. New Energy’s MotionPower™-Heavy technology is designed to capture this kinetic energy when heavy vehicles come to a stop, and subsequently convert this otherwise unused energy into valuable electricity.

“In order to maximize the electricity generated by our MotionPower™ systems, engineers have been working to creatively increase the amount of kinetic energy captured from vehicles while minimizing payload disruption and maintaining driver safety and passenger comfort,” explained Mr. Meetesh V. Patel, President and CEO of New Energy Technologies, Inc.

“As a result, several weeks ago, engineering teams developing our MotionPower™-Auto technology for cars and light trucks achieved a 25-fold increase in energy capture, and today, I’m proud to announce that engineers have now doubled the energy captured by our fluid-driven, Motion-Power™-Heavy technology for heavy trucks, buses, and long haul rigs.”

New Energy's proprietary MotionPower™-Heavy technology is a fluid-based system, uniquely capable of drawing significant amounts of energy from a single vehicle without jarring its payload or creating passenger discomfort. The efficient transfer of energy from heavy vehicles to the MotionPower™-Heavy system ensures greater electricity production and adoption of the device, currently under development.

But from the batteries in a Battery Electric Vehicle (BEV) we want a higher energy density. The capacity to charge and discharge is secondary to the ability to hold a lot of charge (energy). This is because we need battery electric vehicles to go far. These batteries are used to store the energy necessary for locomotion.

A Kinetic Energy Recovery System can surely harvest/collect/store and be designed to distribute electricity for the purposes of recharging an electric vehicles batteries (as in a flywheel) or as electrical energy (as in a battery or supercapacitor).

A flywheel system offers up to twice the efficiency of a battery storage system. The overall in-out efficiency of 65 to 70 percent compares to 35 to 45 percent for a hybrid battery-electric system. That is because it's an entirely mechanical system. In a battery system, kinetic energy has to be converted back and forth to electrical and chemical energy, thus the efficiency losses.

There have been all manner of discussions and research as regards on on board automatic recharging system and I’m not about to disparage out of hand, any of them. Would solar cells serve the purpose? They could if more efficient cells were produced, and I have no doubt that can be accomplished.

They and that discussion do however provide opportunity to clarify a couple of issues. One must have a great deal of power available and regulated for on board recharging. These cells do not serve well in certain weather conditions and night driving, pretty much creating a need for massive storage that just might not be physically possible given other alternatives. And then there is the aesthetic deal.

Let’s face it; Americans have an entrenched notion of what a car should look like and to many solar cells look weird. In fact the electric vehicle that will succeed in the American Market place will look like a traditionally styled automobile and run like one without extended repeated time outs for plug-in recharging requiring more time than a gas fill up.

There have been “electricity producing paints developed” but I admit I can’t quite imagine their application producing the type and amount of electric power required to resolve the issue at hand. The Kenetic Energy solution appears to be the most practical and promising option. The regenerative braking systems employed in several vehicles on the road today make use of Kinetic energy, but in a baby step fashion.

If we assume for the moment that the true electric, zero emissions vehicle will utilize a battery pack electric supply and electric motor power plant then the immediate two needs are better, more efficient batteries and an additional system in the vehicle that is a steady, consistent and sufficient supply of electricity that can be stored, regulated through a sensor system and distributed for purposes of keeping the battery pack charged as necessary so the damn recharging umbilical cord can be trashed and hybrid vehicles become but a temporary, transitional, incremental approach vehicle.

I grant you that a hybrid car, limited as they are can for the moment be of value in the world of “The Urban Commute”, but that sales pitch needs to be ditched and we need to be on the way to an automotive revolution.

If (WHEN) it is built: it will sell!!!!

Other Readings:

Get Beyond The KERS Braking System..Please!

Porsche 911 GT3 R Hybrid

The new Porsche 997 GT3 R Hybrid debuts at the Geneva Motor Show 2010th to see the hybrid technology in the car was from the Williams Formula One team and is based on the F1 Kinetic Energy Recovery Systems (KERS) is based, so they do not race in 2009. Unlike other developed KERS for Formula 1, the Williams system for the use of kinetic energy stored in a flywheel instead of batteries. The GT3-R has two electric motors, each developing 80 hp (60 kW), driving the front wheels add to the 480 hp (360 kW) four-liter six-cylinder engine to the rear. It is intended that the car in the 2010 24 hour race to power. As part of the construction of the 24-hour race in the GT3 hybrid of his racing debut at the 57th ADAC Westfalen driving on the Nürburgring on 27 March 2010.

Chrysler Unplugged: Zero Emissions Venture GEM Sold

Automoblog.net (blog)

Though Chrysler has no 2011 model year electric or even hybrid gas/electric cars, the American automaker is not completely abandoning the pursuit of zero emission vehicles. For summer of this year, the Ram truck brand will offer a plug-in hybrid ...See all stories on this topic »

Automoblog.net (blog)

Though Chrysler has no 2011 model year electric or even hybrid gas/electric cars, the American automaker is not completely abandoning the pursuit of zero emission vehicles. For summer of this year, the Ram truck brand will offer a plug-in hybrid ...See all stories on this topic »

2011 Nissan Leaf: Fear and charging in Boston

Boston Globe

First, a big bow to the 2011 Nissan Leaf, the newest all-electric car from a mainstream automaker in 11 years. Other than a few late-'90s debuts, most affordable electric cars have been glorified golf carts or hacked piecemeal from China. ...See all stories on this topic »

Boston Globe

First, a big bow to the 2011 Nissan Leaf, the newest all-electric car from a mainstream automaker in 11 years. Other than a few late-'90s debuts, most affordable electric cars have been glorified golf carts or hacked piecemeal from China. ...See all stories on this topic »

Two Chevy Volts Catch Fire in One Week!

Fox News (blog)

... even though the car was unplugged. Now General Motors is sending a team of investigators to examine the electric car at Mr Connors's home in Barkhamsted, Connecticut. Mr Connors's two hybrid cars, the nearly-new Volt and an older Suzuki which he ...See all stories on this topic »-

Fox News (blog)

... even though the car was unplugged. Now General Motors is sending a team of investigators to examine the electric car at Mr Connors's home in Barkhamsted, Connecticut. Mr Connors's two hybrid cars, the nearly-new Volt and an older Suzuki which he ...See all stories on this topic »-

A Winter in the Chevy Volt

Cars.com (blog)

There is one thing today that separates an electric car from a gasoline car. Its power comes from a battery, and that battery needs to be recharged. This fundamental shift in how car owners think about refueling their vehicles is why Cars.com purchased ...See all stories on this topic »

Cars.com (blog)

There is one thing today that separates an electric car from a gasoline car. Its power comes from a battery, and that battery needs to be recharged. This fundamental shift in how car owners think about refueling their vehicles is why Cars.com purchased ...See all stories on this topic »

Why Yes, a Fully Charged Nissan Leaf Can Go 87 Miles with Range to Spare

MotorTrend Magazine (blog)

Inquisitive passersby have had loads of questions regarding the cutesy electric carand, not surprisingly, the most frequent topic concerns range. “How far can it go?” “How far have you driven?” “Have you ever run out of power? ...See all stories on this topic »-

MotorTrend Magazine (blog)

Inquisitive passersby have had loads of questions regarding the cutesy electric carand, not surprisingly, the most frequent topic concerns range. “How far can it go?” “How far have you driven?” “Have you ever run out of power? ...See all stories on this topic »-

Barkhamsted Garage Fire Investigation Involving Chevrolet Volt Now in Hands of ...

Hartford Courant

By JANICE PODSADA, jpodsada@courant.com The Hartford Courant State fire marshals have wrapped up their investigation of a Barkhamsted fire that destroyed a garage housing two electric cars, a do-it-yourself-conversion and a new Chevrolet Volt, ...See all stories on this topic »

Hartford Courant

By JANICE PODSADA, jpodsada@courant.com The Hartford Courant State fire marshals have wrapped up their investigation of a Barkhamsted fire that destroyed a garage housing two electric cars, a do-it-yourself-conversion and a new Chevrolet Volt, ...See all stories on this topic »

Mobile Web Development: Beyond the Buzzwords

RCR Unplugged

This is great publicity for the HTML standard, but to call most content available today 'HTML5,' strikes me a little like calling a car with power windows an 'electric vehicle'. In the midst of the HTML5 hype, developers are scratching their heads ...See all stories on this topic »

RCR Unplugged

This is great publicity for the HTML standard, but to call most content available today 'HTML5,' strikes me a little like calling a car with power windows an 'electric vehicle'. In the midst of the HTML5 hype, developers are scratching their heads ...See all stories on this topic »

The Apartment Dweller and the Leaf – Days 4 and 5 and the Conclusion

MotorTrend Magazine (blog)

Options certainly exist for charging the car, but none is nearly as practical as the old gas station. I could make it work, but would I? If I'm completely honest, no. I like electric cars, what they're capable of and what they represent. ...See all stories on this topic »

MotorTrend Magazine (blog)

Options certainly exist for charging the car, but none is nearly as practical as the old gas station. I could make it work, but would I? If I'm completely honest, no. I like electric cars, what they're capable of and what they represent. ...See all stories on this topic »

Hinkle only reaffirms my point re: Plug-In Hybrids

Hinkle: U.S. Energy Policy Should Be 'All Of The Above'

By A. BARTON HINKLE : Published: May 13, 2011

Given the red-team/blue-team dynamic of American politics, it was probably inevitable that discussion of energy policy would degenerate into a debate between drillers and renewers — between those who want more domestic oil exploration to the exclusion of other power sources, and those who want the U.S. to kick its petroleum habit entirely. Both sides are being unrealistic.

Even with painful conservation measures and a crash program to develop alternative energy supplies, the United States will be relying on fossil fuels for many years to come. That's not oil-company propaganda. It's the conclusion of the National Academy of Sciences, which says even hundreds of billions of dollars devoted to plug-in electric cars would not change American gasoline consumption for at least a couple of decades.

But suppose the U.S. could switch to an all-electric fleet overnight. Assuming the entire grid did not melt from the demand spike, where would the electricity come from? Primarily from coal-burning and nuclear power plants. Alternative energy sources such as wind and biomass are utterly incapable of generating the juice necessary to meet current demand, let alone the energy needed to power millions of cars and trucks.

Consider: The U.S. uses nearly 4 terawatts of energy per year (a terawatt is 1 trillion watts). According to Reason magazine's science editor, Ronald Bailey, relying on the work of MIT's Daniel Nocera, putting a windmill on every available spot on the globe that has class 3 winds or higher — i.e., winds in excess of 11.5 mph — would produce 2.1 terawatts at best. And we're not going to be piping in wind energy from the Mongolian steppes. Biomass could produce 10 terawatts — if every person on the planet stopped eating, and we converted all of the world's crops into fuel for machines instead of people.

Even if the current grid did supply enough electricity to power our transportation needs, the U.S. still would have to rely on gasoline for a great deal of its movement. Take the Chevy Volt, America's best-selling electric vehicle. It averages a mere 30-40 miles on battery power alone.

Then it needs to recharge for 10 hours. The Volt is a four-door compact. Imagine how long it would take to recharge a school bus. And if you leave the Volt unplugged in cold weather, then the engine must burn gasoline until the battery warms up to its minimum functioning temperature — somewhere between 32 and 50 degrees Fahrenheit.

Foes of measures to expand drilling — such as the bill passed by the House last week that would open up Virginia's shores for exploration — point out that America consumes 22 percent of the world's energy but contains only 1.5 percent of proven petroleum reserves. Note the word "proven": It refers to the amount of commercially recoverable petroleum available under current government regulations.

In other words, no matter how much petroleum someplace such as the Arctic National Wildlife Refuge contains, if drilling is forbidden there by federal policy then it doesn't count as part of the U.S. reserve. Critics who say we shouldn't permit drilling off Virginia's coast because the U.S. has only a small share of the world's proven reserves are making a circular argument. If drilling were permitted, then we would have much bigger reserves.

All of the above constitute arguments for continued exploration and drilling. What they don't constitute are arguments against developing alternative energy sources. Yet many red-team cheerleaders for oil and gas insist that pursuing alternative energy sources is a fool's errand. It isn't. Just because they cannot meet our needs today does not mean they never will, and insisting otherwise is akin to astronomer F.R. Moulton's 1932 prediction that "there is no hope for the fanciful idea of reaching the moon, because of insurmountable barriers to escaping the Earth's gravity." Human ingenuity knows few limits.

While wind likely will remain of limited benefit, solar energy holds great potential. As Reason's Bailey notes, more energy from the sun strikes the planet in one hour than humanity uses in the course of an entire year. The trick is figuring out how to harness it in economically feasible ways. Unlike nuclear power, solar energy doesn't leave behind deadly toxic waste. Unlike petroleum, solar power is not — at least for human purposes — finite. And unlike coal, oil and gas, it does not contribute to global warming.

(Conservatives, who like to think of themselves as hard-nosed realists, are going to have to stop denying the realities of climate change. True, not everything is known. But not everything is known about gravity, either, and it's still not safe to jump off a bridge.)

Of course, solar power presents challenges of its own — e.g., nightfall. And there are environmental objections, too. When several companies proposed building solar arrays in the Mojave Desert last year, Wildlands Conservancy's executive director said it "would destroy the entire . . . ecosystem," and Calif. Sen. Dianne Feinstein introduced legislation to stop them.

That might be the biggest obstacle to our energy solutions of all: No matter which way the country turns, someone is standing in the way yelling, "Stop!" But given realistic projections of supply and demand, we shouldn't be arguing whether to develop this energy source or that one; we should be developing them all.

No comments:

Post a Comment